Film application machine roller

Film application machine roller

Film application machine roller

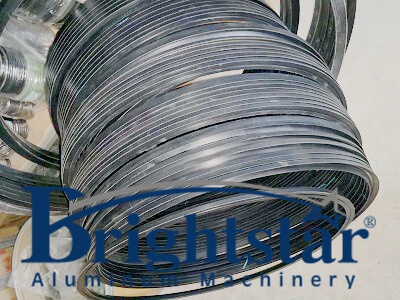

Roller for aluminum profile flim applicator machine

Same as tape applicator machine roller, film sticking machine roller and foil application machine roller, made by Polyurethan and one kind of spare part of aluminum profile film application machine.

Polyurethane (PU) performance introduction:

Polyurethane elastomer has abrasion resistance, chemical resistance, tensile strength, high elasticity, high pressure load resistance, high abrasion resistance, strong shock absorption, tear resistance, radiation resistance, high strength, high load bearing and shock absorption Good performance such as buffering. Good adhesion to metal, while having a wide hardness range. It has superior cushioning plate for shock absorption and shock absorption. It is more impact resistant than metal springs and does not hurt the mold.

Polyurethane elastomer has large load-bearing capacity, abrasion resistance, oil resistance, strong adhesion to the metal skeleton, and can be used to make rubber wheels, guide wheels, pulleys for cable cars, etc. widely used in various transmission mechanisms.

Polyurethane roller is considered the fifth largest plastic! Because of its excellent performance, it is widely used in light industry, chemical industry, electronics, textile, machinery, printing, metallurgy and other industries!

Casting polyurethane rubber roller is a rubber roller made from liquid polyurethane rubber by casting method!

Compared with ordinary rubber rollers, it has higher mechanical strength (2-3 times that of natural rubber), excellent abrasion resistance (5-10 times that of natural rubber), outstanding compression resistance, and hardness range Wide, and still high elasticity under high hardness.(This is a characteristic that other rubber rollers do not have.) High surface finish and superior machining performance. Adhesion to metal is much higher than ordinary rubber. More suitable for use at a certain line speed and high pressure.

Casting polyurethane rubber rollers are roughly divided into polyester type, polyether type and polycaprolactone type.

Polyester type is widely used in low and medium hardness rubber rollers. It has high physical and mechanical properties and good solvent resistance. It is often used in the non-ferrous metal industry.

Polyether type is often used in high speed, high hardness rubber rollers, it has good water resistance, excellent low temperature resistance, good process performance! Commonly used in the manufacture of drawing rollers, printing rollers, etc.

Polycaprolactone is superior in comprehensive performance, low temperature resistance and hydrolysis resistance. It is commonly used as a press roller and a rubber roller with higher requirements.

We offer the dedicated roller for aluminum profile film applicator machine,one stop service.Also old one roller can be renewed here for your machine.